APPLICATIONS

AMUSEMENT RIDES

BAGGAGE HANDLING

PUBLIC TRANSPORT

INDUSTRIAL APPLICATIONS

RENEWABLE ENERGY SOLUTIONS

MAGNETIC BRAKES

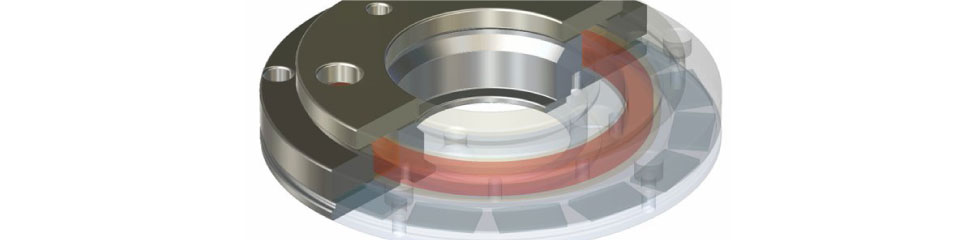

Magnetic Brakes

Force Engineering has supplied permanent magnet brakes (PMB) for use in public rapid transport systems, materials handling and amusement ride applications giving operators the confidence of power free, reliable braking. PMBs are used to smoothly decelerate vehicles approaching stations or loading points as well as control vehicle speed whilst on track.

Permanent magnets produce a braking force on a moving reaction plate as it passes over or between the magnet modules. The braking force generated is typically proportional to the speed of the reaction plate; the faster the conductor is moving, the higher the braking force generated. As there is no contact between the PMB and the reaction plate, there is no wear on either element so the system is virtually maintenance free.

Force Engineering custom designs each PMB solution ensuring the optimal result every time with no control or feedback equipment required further reducing costs and maintenance requirements.

The standard magnetic brake unit consists of high strength rare earth magnets in a housing protected against corrosion with a stainless steel cover fitted to provide mechanical protection. Whilst the PMBs are usually fixed in-track, the units can be mounted on the vehicle giving greater flexibility in the design.

If a PMB system is combined with a Linear Induction Motor drive then the same reaction plate can be used for both elements reducing overall complexity and cost.

The high level of braking force that can generated combined with no moving parts and no external power supply requirement make for a completely reliable fail safe braking system.

Key advantages of permanent magnet brakes;

- Fail safe in all conditions

- Compact size

- Efficient

- Simple to use

- Very low maintenance